Modified Atmosphere Cold Storage

Product Details:

- Usage Keep Product Fresh

- Warranty Yes

- Function Cooling Purposes

- Application Industrial And Commercial

- Voltage 220-440 Volt (v)

- Product Type Frozen Cold Storage

- Click to View more

Modified Atmosphere Cold Storage Price And Quantity

- 1000 Ton

- INR

Modified Atmosphere Cold Storage Product Specifications

- Cooling Purposes

- Frozen Cold Storage

- Yes

- Keep Product Fresh

- 220-440 Volt (v)

- Industrial And Commercial

Modified Atmosphere Cold Storage Trade Information

- 5000 Ton Per Year

- 1 Months

- All India

- We are ISO 9001:2008 and ISO 22000:2005 certified.

Product Description

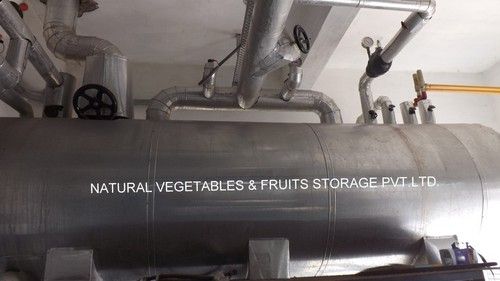

With the help of our skilled workforce and state-of-the-art infrastructure facility, we bring forth for our customers Modified Atmosphere Cold Storage. Commonly installed in grocery, fish, meat, fruit and vegetable stores, our storage system can keep the food items colder while retaining their taste and aroma for longer period. Featured with an electric condenser, compressor and evaporator our storage system keeps the food items secure from exterior heat, temperature and electric shocks. Furthermore, our offered Modified Atmosphere Cold Storage is appreciated for easy installation & maintenance, robust construction, thermal insulation, low power consumption and longer service life.

Our offered Cold Storage Systems are widely installed in meat, grocery, fish, vegetables and fruit store for keeping these items cool and also for retaining their aroma and taste for long time. For these purposes these systems are installed with compressor, electric condenser and evaporator. Also our systems are designed for preventing the food items from temperature, exterior heat and electric shocks.

We also assist you in providing in-depth solutions at farm level whether it is the handling of the produced crops or transportation and supply to the end users. We continuously monitor the temperature, humidity and other parameters which are desirable for the deliverance of produce in marketable circumstances.

For retaining the quality of produce frozen products are required to be transported and stored in an uninterrupted cold chain. Proper temperature needed to be maintained from the place of production to the final destination. If the produce is exposed to the temperature above the recommended range, then its quality may get lowered. For the quality maintenance of the produce during the whole transportation process, we undertake below given procedures:

TEMPERATURE MONITORING:

One should always keep in mind that the cold chain can be broken anytime. Although there are several digital monitoring systems of transported or stored goods, the problem still exists in the food segment. These devices are developed in a way so that they can only monitor the temperature of the surroundings which is the temperature of the vehicle or the storing place; however, they are unable to measure the temperature of the products. This chain gets easily broken at the moment of reloading of goods. It results in creating misunderstandings among the producer, Transport Company and distributor, and affects the business relationship. In that condition, either the producer or the transport company has to take the responsibility of breaking the cold chain that resulted in damage to the goods.

HACCP METHOD:

HACCP (Hazard Analysis and Critical Control Point) needs to be undertaken for ensuring the protection of groceries produced and sold for consumers. HACCP method is used by the companies dealing in the trade of groceries. It is chiefly based on preventing the threats. It is done by identification of places where the threats can take place and the suitable action takes suddenly in the case of threat is recognized. HACCP legislation restrains the temperature change through monitoring the product's sensitive temperature that is prone to be changed. With such a quick effect, TTI indicators are the ultimate tools that let the producers to execute this condition. The application of TTI indicators on the stage of combined or single pack will make sure continuous measurement of the temperature of the product monitored and will also specify the likelihood of the cold chain break.

NOTE:

Even the best managed frozen product can lose the quality due to even a slight omission in storage, transportation or selling process. The focus is chiefly put on these cells of the cold chain because the researchers have proved that these are the potential points where the biggest threats of decreasing the quality of frozen products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Cold Storage System' category

(Nsspl)

|

Natural Storage Solutions Pvt. Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |