Vertical Milling Job Work

Product Details:

X

Vertical Milling Job Work Price And Quantity

- 1 , , Unit

Vertical Milling Job Work Trade Information

- 1 Months

Product Description

Vertical Milling Job Work

Product Details

|

Number of Pieces |

<100 Pieces |

|

Application/Usage |

Industrial |

|

Job Order Frequency |

Regular |

|

Work Piece Material |

Aluminium |

|

Product Material |

Steel |

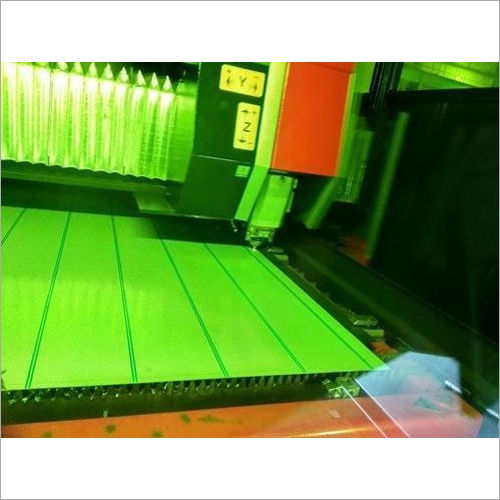

High-Precision Vertical Milling Services

Utilizing robust vertical milling machines, we deliver precise machining for industrial components. Our equipment supports a max table size of 1200 mm x 350 mm, making it ideal for handling various metal fabrication projects with stringent tolerance requirements. Customers benefit from expert workmanship, quick service, and versatile application in demanding industries such as automotive, aerospace, and machinery.

Flexible Service Modes Nationwide

We provide both onsite and offsite vertical milling job work throughout India. Clients can choose the most suitable service mode based on their production schedule or project urgency. This flexibility ensures minimal downtime and maximizes operational efficiency for businesses needing consistent machining support.

FAQs of Vertical Milling Job Work:

Q: How does your vertical milling job work process ensure high precision?

A: Our vertical milling job work uses advanced machines capable of holding tolerances up to 0.01 mm. Precision is maintained by combining skilled operators with well-maintained machinery and careful process monitoring, ensuring that every component meets strict industry standards.Q: What types of industries can benefit from your vertical milling services?

A: Our services are tailored for a range of sectors, including automotive, aerospace, and machinery manufacturing. These industries often require exacting specifications for metal components, which our vertical milling capabilities can deliver with accuracy and reliability.Q: Where do you offer your vertical milling machining services?

A: We provide our vertical milling job work services across India, supporting clients both onsite at their facilities and offsite at our state-of-the-art workshops. This nationwide reach ensures convenient and efficient service regardless of project location.Q: When should a manufacturer opt for vertical milling job work?

A: Manufacturers should consider vertical milling job work when they require high-precision machining of metal components, particularly for prototypes, small batches, or custom parts. Our service is ideal for situations demanding tight tolerances or complex geometries.Q: What is the typical process for initiating a vertical milling job work order?

A: The process starts with a consultation to understand your component needs and specifications. After evaluating drawings or samples, we provide a quotation, schedule the job, and commence machining either onsite or offsite as agreed. Quality checks follow before delivery or component installation.Q: How can vertical milling services improve the manufacturing workflow of my business?

A: Outsourcing vertical milling job work to experts increases efficiency by minimizing setup time, reducing manpower needs, and enhancing part accuracy. It allows manufacturers to focus on core competencies while ensuring consistent quality in machined components.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Job Work' category

Contact Details

Natural Storage Solutions Pvt. Ltd.

(Nsspl)

(Nsspl)

Plot No.3,4,5, Jagnath Plot Corner, Dr.Radha Krushna Road, Opp. Rajkumar College, Rajkot - 382729, Gujarat, India

Phone :08045475730

|

Natural Storage Solutions Pvt. Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |